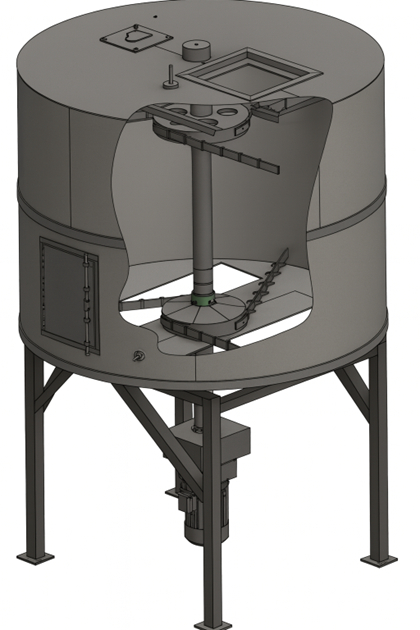

Dosing hoppers

Receipt and storage

Dosing hoppers are used for the precise and continuous dosing of bulk materials such as sawdust, wood chips, pellets, or other biomass. They are a key component in technological units where it is necessary to ensure a uniform supply of material to downstream equipment, such as boilers, conveyors, presses, or dryers.

The hoppers are designed to minimize the risk of material flow interruption and allow for precise regulation of the material quantity according to current operational needs. This ensures optimal use of resources, higher equipment efficiency, and reduced operational losses.

The dosing mechanism can be implemented in various ways – for example, using a screw feeder, vibrating bottom, or dosing flap – depending on the type and properties of the material. The hoppers are available in various volumes and with the option of automatic control or connection to the control system of the entire technology.